SPOILER ALERT!

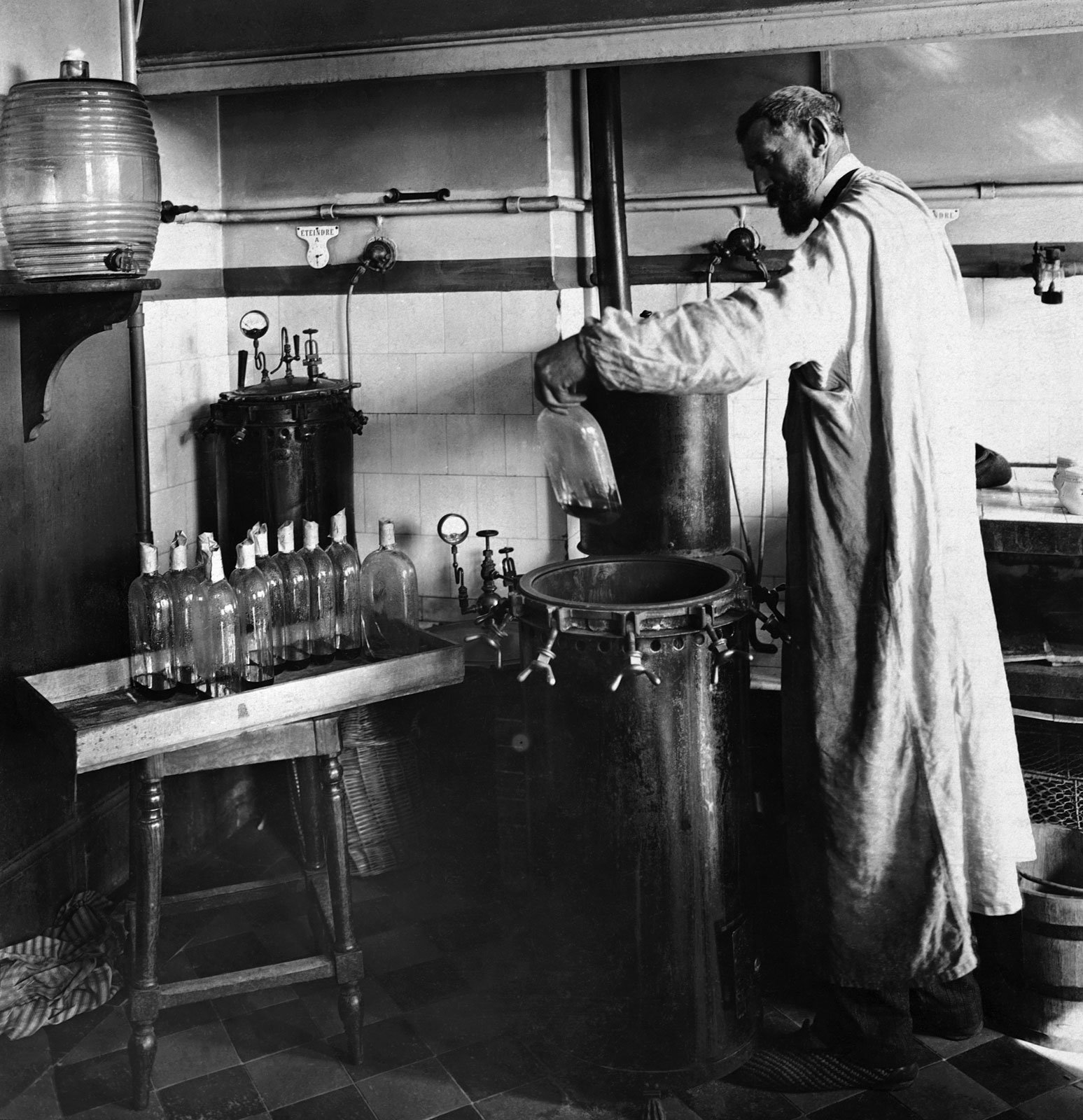

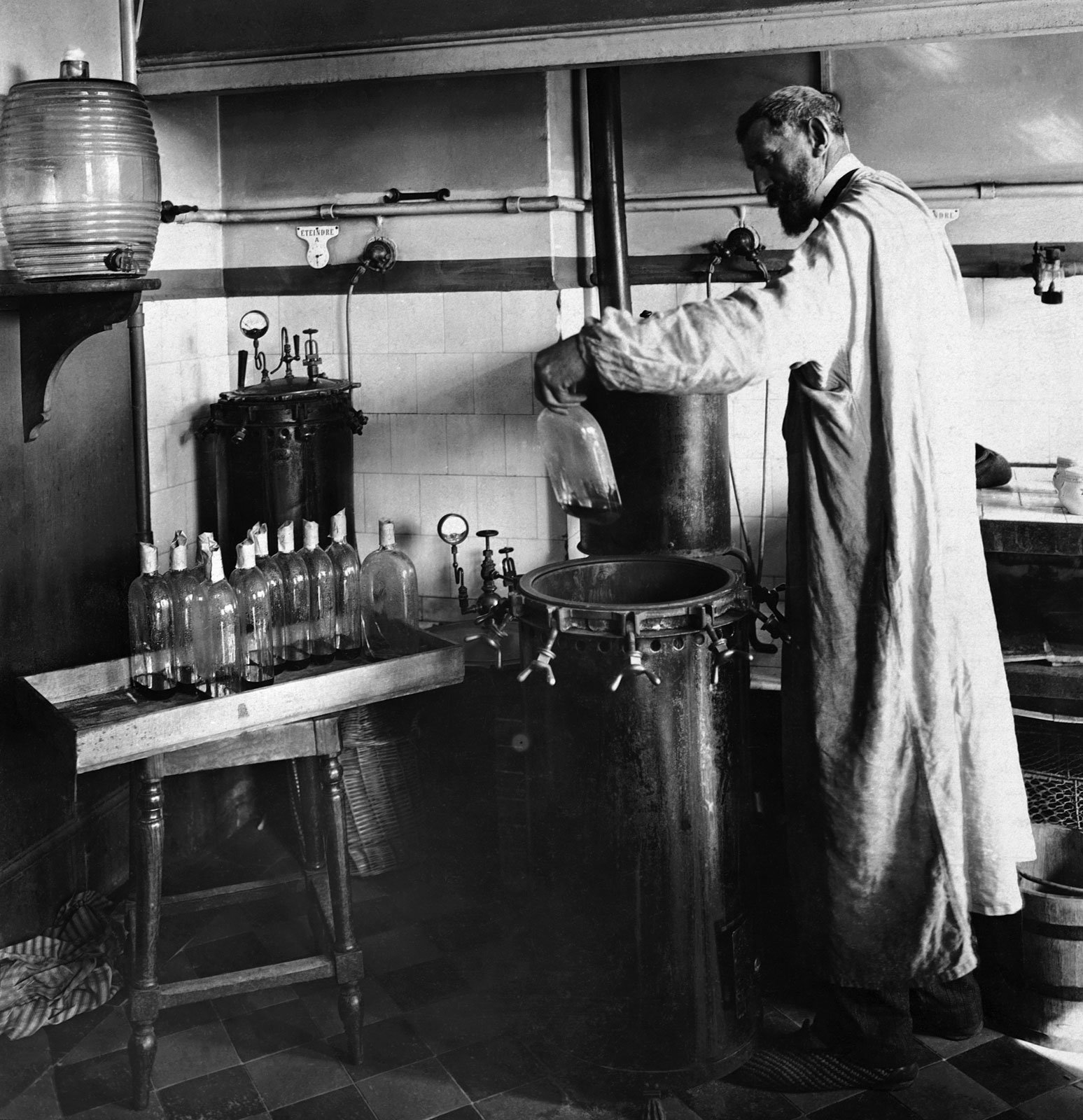

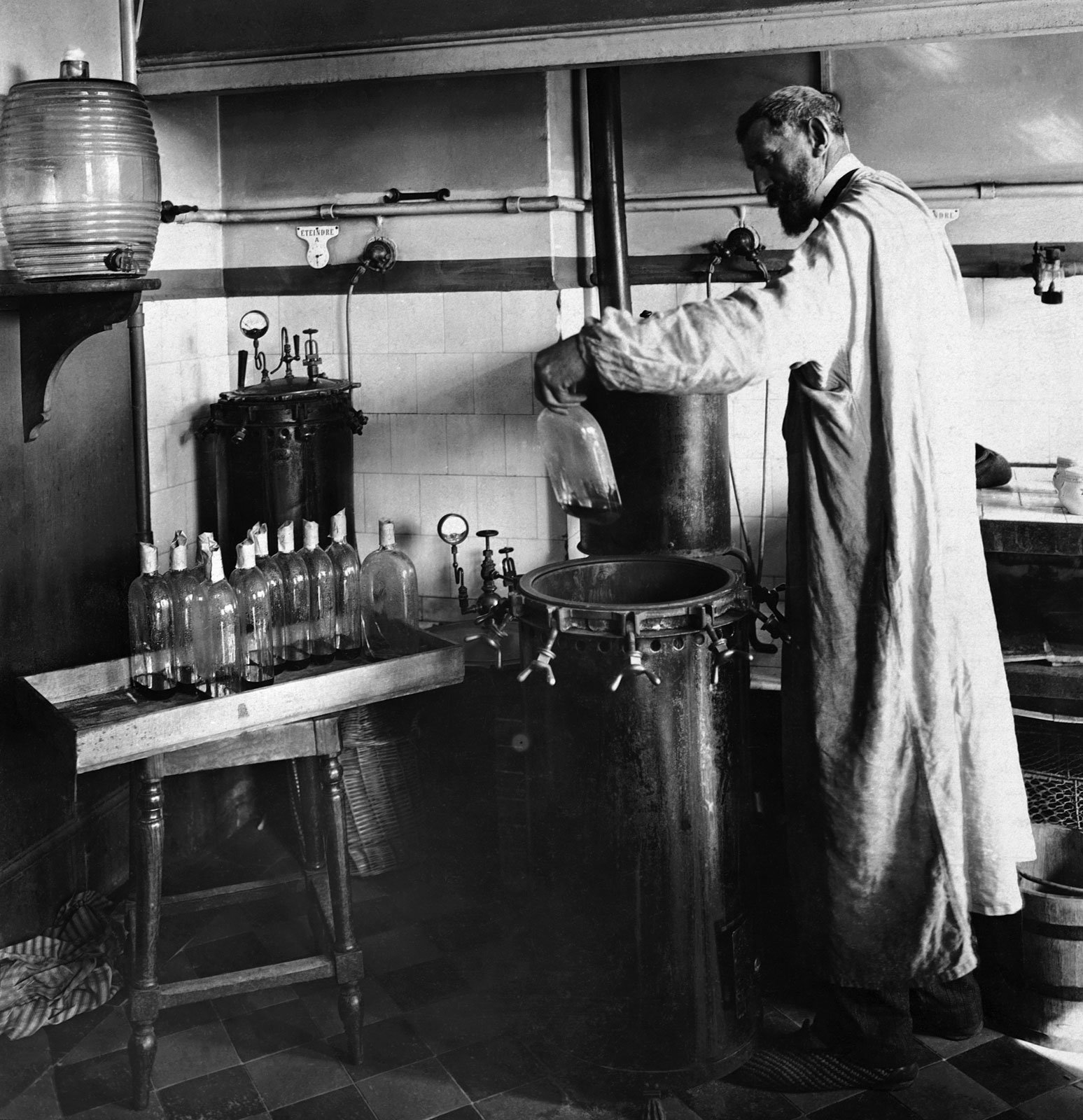

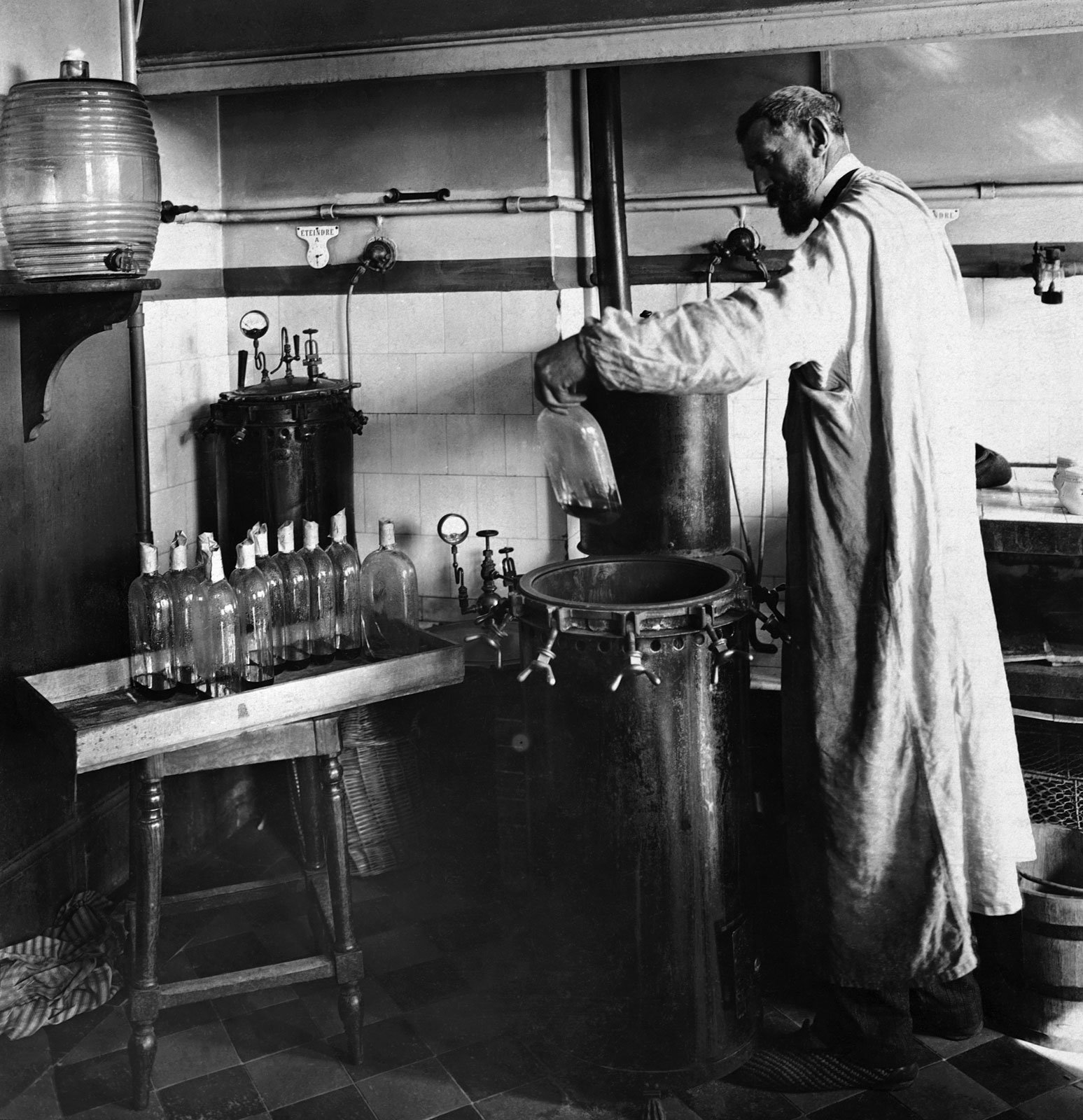

Transforming Food Processing: Important Developments In Batch Pasteurizers You Ought To Be Aware Of

Web Content Create By-Jonsson Warner

As you take into consideration the future of food handling, have you ever before questioned the current advancements in batch pasteurizers that could revolutionize the market? Picture a globe where performance, food safety, and sustainability are perfectly incorporated right into the process, providing a glance of what's to come. Remain tuned to discover how these developments are reshaping the way food is refined and exactly how they may influence your operations in the near future.

## Improved Performance Via Automation

Seeking to simplify your pasteurization procedure? batch pasteurizers currently provide enhanced efficiency with automation. By incorporating advanced technology, these modern systems can substantially improve the speed and accuracy of your pasteurization procedures.

With automated controls and sensing units, you can specifically keep track of and readjust factors such as temperature level and stress, making certain ideal pasteurization conditions for your items.

Automation likewise minimizes the need for manual intervention, conserving you time and labor prices. These advanced batch pasteurizers can instantly control the flow of items, find abnormalities, and also alert operators in case of any kind of concerns. This not only increases the total effectiveness of your pasteurization process yet also enhances the uniformity and high quality of your final products.

Moreover, automation aids in lessening the threat of human mistakes, causing more trustworthy and secure food processing. With these developments in batch pasteurizers, you can simplify your procedures, enhance performance, and maintain top quality standards in your food processing facility.

## Enhanced Food Security Specifications

To ensure the highest degree of food safety and security in your procedures, it's crucial to execute improved standards that straighten with regulatory requirements and market best practices. Enhancing food safety requirements involves extensive tracking of crucial control factors, comprehensive hygiene methods, and detailed personnel training. Routine audits and examinations aid in recognizing possible dangers and ensuring conformity with strict guidelines.

Buying advanced technologies such as automated monitoring systems and data analytics can additionally boost your food safety measures. These advancements offer real-time insights into the production procedure, making it possible for punctual rehabilitative actions when discrepancies occur.

Implementing Threat Evaluation and Crucial Control Factors (HACCP) concepts is essential for systematically dealing with food safety threats and protecting against contamination.

## Lasting Practices in Pasteurization

Incorporating lasting techniques in pasteurization is essential for decreasing ecological effect and improving operational performance. By executing click this link now -efficient innovations, such as warm healing systems and automated controls, you can reduce source intake throughout the pasteurization process. Utilizing water-saving strategies, like counter-current rinsing systems and recycling rinse water, aids in conserving this priceless source.

Furthermore, enhancing cleansing processes to lower chemical use and wastewater generation further boosts sustainability in pasteurization operations.

Selecting eco-friendly product packaging products and executing reusing programs for product packaging waste can considerably minimize the total environmental footprint of your pasteurization processes. https://www.mensjournal.com/news/beer-popularity-declining-alcoholic-consumption-trends-2023 with providers who prioritize sustainable sourcing practices guarantees that the ingredients made use of in your products are created properly.

Furthermore, investing in renewable energy sources, such as solar or wind power, for your pasteurization centers can assist reduced greenhouse gas discharges and relocate towards a more lasting future in food handling. By accepting lasting practices in pasteurization, you not just add to ecological conservation yet likewise enhance the overall performance and resilience of your food processing procedures.

## Final thought

To conclude, embracing advancements in batch pasteurizers can reinvent the food handling sector by enhancing effectiveness, guaranteeing food safety and security, and advertising sustainability. By integrating automation attributes, improving food safety criteria, and taking on sustainable methods, firms can remain ahead of the contour and meet the developing needs of customers and regulatory bodies. Keep positive in implementing these advancements to remain competitive and drive favorable adjustment in the food processing field.

As you take into consideration the future of food handling, have you ever before questioned the current advancements in batch pasteurizers that could revolutionize the market? Picture a globe where performance, food safety, and sustainability are perfectly incorporated right into the process, providing a glance of what's to come. Remain tuned to discover how these developments are reshaping the way food is refined and exactly how they may influence your operations in the near future.

## Improved Performance Via Automation

Seeking to simplify your pasteurization procedure? batch pasteurizers currently provide enhanced efficiency with automation. By incorporating advanced technology, these modern systems can substantially improve the speed and accuracy of your pasteurization procedures.

With automated controls and sensing units, you can specifically keep track of and readjust factors such as temperature level and stress, making certain ideal pasteurization conditions for your items.

Automation likewise minimizes the need for manual intervention, conserving you time and labor prices. These advanced batch pasteurizers can instantly control the flow of items, find abnormalities, and also alert operators in case of any kind of concerns. This not only increases the total effectiveness of your pasteurization process yet also enhances the uniformity and high quality of your final products.

Moreover, automation aids in lessening the threat of human mistakes, causing more trustworthy and secure food processing. With these developments in batch pasteurizers, you can simplify your procedures, enhance performance, and maintain top quality standards in your food processing facility.

## Enhanced Food Security Specifications

To ensure the highest degree of food safety and security in your procedures, it's crucial to execute improved standards that straighten with regulatory requirements and market best practices. Enhancing food safety requirements involves extensive tracking of crucial control factors, comprehensive hygiene methods, and detailed personnel training. Routine audits and examinations aid in recognizing possible dangers and ensuring conformity with strict guidelines.

Buying advanced technologies such as automated monitoring systems and data analytics can additionally boost your food safety measures. These advancements offer real-time insights into the production procedure, making it possible for punctual rehabilitative actions when discrepancies occur.

Implementing Threat Evaluation and Crucial Control Factors (HACCP) concepts is essential for systematically dealing with food safety threats and protecting against contamination.

## Lasting Practices in Pasteurization

Incorporating lasting techniques in pasteurization is essential for decreasing ecological effect and improving operational performance. By executing click this link now -efficient innovations, such as warm healing systems and automated controls, you can reduce source intake throughout the pasteurization process. Utilizing water-saving strategies, like counter-current rinsing systems and recycling rinse water, aids in conserving this priceless source.

Furthermore, enhancing cleansing processes to lower chemical use and wastewater generation further boosts sustainability in pasteurization operations.

Selecting eco-friendly product packaging products and executing reusing programs for product packaging waste can considerably minimize the total environmental footprint of your pasteurization processes. https://www.mensjournal.com/news/beer-popularity-declining-alcoholic-consumption-trends-2023 with providers who prioritize sustainable sourcing practices guarantees that the ingredients made use of in your products are created properly.

Furthermore, investing in renewable energy sources, such as solar or wind power, for your pasteurization centers can assist reduced greenhouse gas discharges and relocate towards a more lasting future in food handling. By accepting lasting practices in pasteurization, you not just add to ecological conservation yet likewise enhance the overall performance and resilience of your food processing procedures.

## Final thought

To conclude, embracing advancements in batch pasteurizers can reinvent the food handling sector by enhancing effectiveness, guaranteeing food safety and security, and advertising sustainability. By integrating automation attributes, improving food safety criteria, and taking on sustainable methods, firms can remain ahead of the contour and meet the developing needs of customers and regulatory bodies. Keep positive in implementing these advancements to remain competitive and drive favorable adjustment in the food processing field.

SPOILER ALERT!

Checking Out The Distinctions Between Tunnel Pasteurizers And Batch Pasteurizers: Which Is The Preferred Technique?

Writer-Block Thisted

When choosing between Tunnel pasteurizers and batch pasteurizers, you may ask yourself which option fits your manufacturing requires best. Elements like production volume, running expenses, and item top quality all come into play when making this crucial selection. Recognizing hop over to this web-site and restrictions of each system can help you make an enlightened decision that aligns with your service objectives and top quality requirements. Stay tuned to find crucial insights that will guide you in selecting the ideal pasteurization service for your certain requirements.

## Performance and Throughput

When comparing Tunnel pasteurizers to batch pasteurizers in terms of effectiveness and throughput, the former generally outshines the last in constant handling capabilities. Tunnel pasteurizers are designed for constant processing, allowing for a constant circulation of items via the system. This configuration allows greater throughput prices contrasted to batch pasteurizers, which run in cycles with pauses between each batch.

The constant circulation in Tunnel pasteurizers results in a much more efficient processing approach, decreasing traffic jams and making best use of manufacturing result.

In addition, Tunnel pasteurizers provide better temperature level control throughout the whole process. The consistent temperature levels preserved in Tunnel pasteurizers guarantee uniform pasteurization of items, enhancing performance and top quality.

In contrast, batch pasteurizers may experience temperature level fluctuations between batches, potentially influencing the general performance of the pasteurization procedure.

## Price Evaluation

To additionally assess the functionality of Tunnel pasteurizers versus batch pasteurizers, a critical facet to consider is the price analysis. Tunnel pasteurizers typically have a greater upfront expense as a result of their automated and continuous procedure, yet they provide substantial cost savings in labor expenses gradually. On the other hand, batch pasteurizers have a reduced first financial investment but may call for even more manual work, enhancing operational expenses in the future.

When examining the cost-effectiveness of each alternative, it's vital to consider not just the purchase price however likewise ongoing expenses like energy intake, maintenance, and labor. Tunnel pasteurizers often tend to be extra energy-efficient given that they run constantly and use heat recovery systems. batch pasteurizers, while easier in layout, may consume more power throughout each batch processing cycle.

Inevitably, the option between Tunnel and batch pasteurizers will rely on your manufacturing volume, budget restrictions, and long-term functional objectives. Performing an extensive expense evaluation thinking about both immediate and lasting expenditures will certainly aid you identify one of the most cost-efficient solution for your particular demands.

## Item Quality and Shelf Life

For optimal product top quality and expanded service life, the choice in between Tunnel pasteurizers and batch pasteurizers plays a vital role in your production procedure.

Tunnel pasteurizers are recognized for their capacity to give constant and uniform warm distribution throughout the item, making sure that all containers are pasteurized efficiently. This harmony assists keep the high quality of your items by minimizing the threat of under or over-pasteurization.

On https://www.foodengineeringmag.com/articles/99269-biron-teas-brings-batch-mixing-in-house , batch pasteurizers use more adaptability in processing smaller quantities of items with varying recipes or active ingredients. While this adaptability can be helpful in specific situations, it might also result in incongruities in pasteurization degrees, potentially impacting product top quality and life span.

When it concerns life span, the precision and control provided by Tunnel pasteurizers can assist expand the long life of your products by making sure that harmful microbes are efficiently eliminated. This can result in a longer service life for your items, inevitably profiting your business and clients. Take into consideration the details demands of your items and production procedure to determine which pasteurization method straightens finest with your objectives for product top quality and shelf life.

## Verdict

To conclude, when choosing in between Tunnel pasteurizers and batch pasteurizers, it is clear that Tunnel pasteurizers supply remarkable performance, throughput, cost-effectiveness, and product quality. With their continual processing abilities, better temperature level control, and expanded shelf life benefits, Tunnel pasteurizers are the recommended choice for numerous food and drink manufacturers. Make the button to Tunnel pasteurizers for improved lead to your manufacturing process.

When choosing between Tunnel pasteurizers and batch pasteurizers, you may ask yourself which option fits your manufacturing requires best. Elements like production volume, running expenses, and item top quality all come into play when making this crucial selection. Recognizing hop over to this web-site and restrictions of each system can help you make an enlightened decision that aligns with your service objectives and top quality requirements. Stay tuned to find crucial insights that will guide you in selecting the ideal pasteurization service for your certain requirements.

## Performance and Throughput

When comparing Tunnel pasteurizers to batch pasteurizers in terms of effectiveness and throughput, the former generally outshines the last in constant handling capabilities. Tunnel pasteurizers are designed for constant processing, allowing for a constant circulation of items via the system. This configuration allows greater throughput prices contrasted to batch pasteurizers, which run in cycles with pauses between each batch.

The constant circulation in Tunnel pasteurizers results in a much more efficient processing approach, decreasing traffic jams and making best use of manufacturing result.

In addition, Tunnel pasteurizers provide better temperature level control throughout the whole process. The consistent temperature levels preserved in Tunnel pasteurizers guarantee uniform pasteurization of items, enhancing performance and top quality.

In contrast, batch pasteurizers may experience temperature level fluctuations between batches, potentially influencing the general performance of the pasteurization procedure.

## Price Evaluation

To additionally assess the functionality of Tunnel pasteurizers versus batch pasteurizers, a critical facet to consider is the price analysis. Tunnel pasteurizers typically have a greater upfront expense as a result of their automated and continuous procedure, yet they provide substantial cost savings in labor expenses gradually. On the other hand, batch pasteurizers have a reduced first financial investment but may call for even more manual work, enhancing operational expenses in the future.

When examining the cost-effectiveness of each alternative, it's vital to consider not just the purchase price however likewise ongoing expenses like energy intake, maintenance, and labor. Tunnel pasteurizers often tend to be extra energy-efficient given that they run constantly and use heat recovery systems. batch pasteurizers, while easier in layout, may consume more power throughout each batch processing cycle.

Inevitably, the option between Tunnel and batch pasteurizers will rely on your manufacturing volume, budget restrictions, and long-term functional objectives. Performing an extensive expense evaluation thinking about both immediate and lasting expenditures will certainly aid you identify one of the most cost-efficient solution for your particular demands.

## Item Quality and Shelf Life

For optimal product top quality and expanded service life, the choice in between Tunnel pasteurizers and batch pasteurizers plays a vital role in your production procedure.

Tunnel pasteurizers are recognized for their capacity to give constant and uniform warm distribution throughout the item, making sure that all containers are pasteurized efficiently. This harmony assists keep the high quality of your items by minimizing the threat of under or over-pasteurization.

On https://www.foodengineeringmag.com/articles/99269-biron-teas-brings-batch-mixing-in-house , batch pasteurizers use more adaptability in processing smaller quantities of items with varying recipes or active ingredients. While this adaptability can be helpful in specific situations, it might also result in incongruities in pasteurization degrees, potentially impacting product top quality and life span.

When it concerns life span, the precision and control provided by Tunnel pasteurizers can assist expand the long life of your products by making sure that harmful microbes are efficiently eliminated. This can result in a longer service life for your items, inevitably profiting your business and clients. Take into consideration the details demands of your items and production procedure to determine which pasteurization method straightens finest with your objectives for product top quality and shelf life.

## Verdict

To conclude, when choosing in between Tunnel pasteurizers and batch pasteurizers, it is clear that Tunnel pasteurizers supply remarkable performance, throughput, cost-effectiveness, and product quality. With their continual processing abilities, better temperature level control, and expanded shelf life benefits, Tunnel pasteurizers are the recommended choice for numerous food and drink manufacturers. Make the button to Tunnel pasteurizers for improved lead to your manufacturing process.

SPOILER ALERT!

Delve Into The Numerous Pasteurization Remedies That Cater To Your Manufacturing Demands-- Find The Alternative That Is Right For You

Personnel Writer-Bruce Cullen

When determining in between Tunnel pasteurizers and batch pasteurizers, you could question which alternative suits your production needs finest. Aspects like manufacturing quantity, running prices, and product top quality all entered into play when making this crucial selection. Recognizing the unique advantages and restrictions of each system can assist you make an educated choice that aligns with your organization objectives and high quality standards. Remain tuned to uncover vital understandings that will direct you in picking the excellent pasteurization remedy for your particular requirements.

## Effectiveness and Throughput

When comparing Tunnel pasteurizers to batch pasteurizers in terms of effectiveness and throughput, the former typically outperforms the latter in constant processing abilities. Tunnel pasteurizers are designed for constant handling, allowing for a constant circulation of products via the system. This setup makes it possible for higher throughput rates compared to batch pasteurizers, which operate in cycles with stops briefly in between each batch.

The constant flow in Tunnel pasteurizers causes a more reliable handling method, reducing bottlenecks and making best use of production output.

In addition, Tunnel pasteurizers provide far better temperature control throughout the entire process. The regular temperature degrees maintained in Tunnel pasteurizers guarantee uniform pasteurization of items, enhancing effectiveness and high quality.

In contrast, batch pasteurizers might experience temperature level variations between batches, potentially impacting the total efficiency of the pasteurization process.

## Price Evaluation

To further examine the usefulness of Tunnel pasteurizers versus batch pasteurizers, an important element to think about is the expense analysis. Tunnel pasteurizers typically have a higher ahead of time cost as a result of their automated and continual operation, but they provide significant financial savings in labor costs gradually. On the other hand, batch pasteurizers have a lower preliminary investment but might call for even more manual labor, boosting operational costs in the future.

When evaluating the cost-effectiveness of each choice, it's important to consider not just the purchase rate yet likewise ongoing costs like power usage, upkeep, and labor. Tunnel pasteurizers have a tendency to be much more energy-efficient since they operate continually and use heat healing systems. batch pasteurizers, while simpler in style, may take in extra energy during each batch processing cycle.

Ultimately, the selection between Tunnel and batch pasteurizers will certainly depend on your production quantity, budget constraints, and lasting functional objectives. Performing an extensive price evaluation taking into consideration both instant and long-term expenses will help you figure out the most affordable solution for your particular needs.

## Product Quality and Life Span

For ideal item quality and prolonged service life, the choice in between Tunnel pasteurizers and batch pasteurizers plays an important duty in your production process.

Read Homepage are known for their capability to give constant and uniform warmth distribution throughout the item, making sure that all containers are sterilized efficiently. This uniformity aids keep the high quality of your products by minimizing the danger of under or over-pasteurization.

On the other hand, batch pasteurizers supply more versatility in processing smaller quantities of items with differing dishes or active ingredients. While this adaptability can be helpful in specific situations, it might additionally bring about disparities in pasteurization degrees, potentially affecting product top quality and life span.

When it comes to life span, the accuracy and control offered by Tunnel pasteurizers can assist prolong the long life of your items by making sure that damaging microorganisms are efficiently gotten rid of. This can lead to a longer life span for your products, eventually profiting your business and consumers. Take into consideration the details demands of your items and production process to determine which pasteurization method lines up best with your goals for item high quality and life span.

## Verdict

In conclusion, when deciding between Tunnel pasteurizers and batch pasteurizers, it is clear that Tunnel pasteurizers use premium efficiency, throughput, cost-effectiveness, and item high quality. With their continual processing capabilities, better temperature level control, and prolonged service life benefits, Tunnel pasteurizers are the favored choice for numerous food and drink manufacturers. Make the button to Tunnel pasteurizers for boosted cause your manufacturing process.

When determining in between Tunnel pasteurizers and batch pasteurizers, you could question which alternative suits your production needs finest. Aspects like manufacturing quantity, running prices, and product top quality all entered into play when making this crucial selection. Recognizing the unique advantages and restrictions of each system can assist you make an educated choice that aligns with your organization objectives and high quality standards. Remain tuned to uncover vital understandings that will direct you in picking the excellent pasteurization remedy for your particular requirements.

## Effectiveness and Throughput

When comparing Tunnel pasteurizers to batch pasteurizers in terms of effectiveness and throughput, the former typically outperforms the latter in constant processing abilities. Tunnel pasteurizers are designed for constant handling, allowing for a constant circulation of products via the system. This setup makes it possible for higher throughput rates compared to batch pasteurizers, which operate in cycles with stops briefly in between each batch.

The constant flow in Tunnel pasteurizers causes a more reliable handling method, reducing bottlenecks and making best use of production output.

In addition, Tunnel pasteurizers provide far better temperature control throughout the entire process. The regular temperature degrees maintained in Tunnel pasteurizers guarantee uniform pasteurization of items, enhancing effectiveness and high quality.

In contrast, batch pasteurizers might experience temperature level variations between batches, potentially impacting the total efficiency of the pasteurization process.

## Price Evaluation

To further examine the usefulness of Tunnel pasteurizers versus batch pasteurizers, an important element to think about is the expense analysis. Tunnel pasteurizers typically have a higher ahead of time cost as a result of their automated and continual operation, but they provide significant financial savings in labor costs gradually. On the other hand, batch pasteurizers have a lower preliminary investment but might call for even more manual labor, boosting operational costs in the future.

When evaluating the cost-effectiveness of each choice, it's important to consider not just the purchase rate yet likewise ongoing costs like power usage, upkeep, and labor. Tunnel pasteurizers have a tendency to be much more energy-efficient since they operate continually and use heat healing systems. batch pasteurizers, while simpler in style, may take in extra energy during each batch processing cycle.

Ultimately, the selection between Tunnel and batch pasteurizers will certainly depend on your production quantity, budget constraints, and lasting functional objectives. Performing an extensive price evaluation taking into consideration both instant and long-term expenses will help you figure out the most affordable solution for your particular needs.

## Product Quality and Life Span

For ideal item quality and prolonged service life, the choice in between Tunnel pasteurizers and batch pasteurizers plays an important duty in your production process.

Read Homepage are known for their capability to give constant and uniform warmth distribution throughout the item, making sure that all containers are sterilized efficiently. This uniformity aids keep the high quality of your products by minimizing the danger of under or over-pasteurization.

On the other hand, batch pasteurizers supply more versatility in processing smaller quantities of items with differing dishes or active ingredients. While this adaptability can be helpful in specific situations, it might additionally bring about disparities in pasteurization degrees, potentially affecting product top quality and life span.

When it comes to life span, the accuracy and control offered by Tunnel pasteurizers can assist prolong the long life of your items by making sure that damaging microorganisms are efficiently gotten rid of. This can lead to a longer life span for your products, eventually profiting your business and consumers. Take into consideration the details demands of your items and production process to determine which pasteurization method lines up best with your goals for item high quality and life span.

## Verdict

In conclusion, when deciding between Tunnel pasteurizers and batch pasteurizers, it is clear that Tunnel pasteurizers use premium efficiency, throughput, cost-effectiveness, and item high quality. With their continual processing capabilities, better temperature level control, and prolonged service life benefits, Tunnel pasteurizers are the favored choice for numerous food and drink manufacturers. Make the button to Tunnel pasteurizers for boosted cause your manufacturing process.

SPOILER ALERT!

Enhancing Performance: Enhancing Your Production Process Utilizing Tunnel Pasteurization Tools

Material Written By-Bender Santana

Tunnel pasteurizers are big industrial-scale makers that warm and great drinks in order to eliminate microorganisms and prolong their life span. Their efficiency relies on precision control.

A number of drink business have retrofitted their existing Tunnel pasteurizers with brand-new eco-friendly technologies to achieve considerable ecological benefits. These include lowered energy consumption, lower water use and reduced greenhouse gas exhausts.

When you run a brewery, your objective isn't just to eliminate dangerous virus, but also to provide consistency in your products. A well-executed pasteurization procedure not only extends beer's shelf life, but it makes certain that every bottle of your beer will certainly taste the exact same, from your initial set to your last. This is specifically important for craft breweries seeking to bring in health-conscious customers who want the fizzy benefits of soft drinks.

Tunnel pasteurizers work by bringing bottles and containers up to their wanted temperature level in stages, holding them there for long enough to kill off the microorganisms that create putridity. They after that bring them down once more in step-by-step actions until they reach space temperature level, protecting taste accounts. By doing this, they not just prevent microorganisms from increasing in the item, yet they likewise reduce energy consumption by eliminating warmth loss. These are the sort of performance gains that can add up quickly.

As more emphasis is placed on eco-friendly manufacturing techniques, beverage manufacturers are trying to find ways to reduce their waste manufacturing. Tunnel pasteurizers do a terrific job of this, specifically when they are created and developed by seasoned experts.

Tunnel pasteurizers utilize a series of sprays to heat up the bottles or cans as they move with the device. This removes the need for a big vapor container that eats energy and wastes water. Furthermore, Tunnel pasteurizers make use of a water cost savings system to reuse the warm water utilized in the home heating process, which lowers water and drain usage.

Another advantage of Tunnel pasteurization is its compatibility with soft drinks, which is a big marketing point for craft makers that intend to prolong their items' service life and guarantee consistency between sets. Unlike flash pasteurizers, which in some cases deal with high degrees of carbonation, Tunnel devices can handle these effervescent mixtures without breaking a sweat (or a bottle).

When your drinks are properly treated in Tunnel pasteurizers, they're shielded from dangerous germs while preserving their taste accounts. This indicates your mixtures, sodas, acid maintains (like fruits or acids), and wellness shots can prolong their service life without losing their trademark taste.

In order to accomplish this, passages include specific temperature level control and even circulation throughout their several phases. In addition, conveyor belt speeds help guarantee equal treatment times for each container going into the equipment. All this assists you ensure top quality results every time.

Lastly, tunnels are compatible with carbonated beverages, an expanding fad among health-conscious consumers searching for fizzy choices to sugary soft drinks. Unlike flash pasteurizers, which can struggle with high-carbonation levels, Tunnel machines are created to manage them.

Moreover, visit this hyperlink with power recovery systems decreases water usage too. By utilizing the recovered water for air conditioning, you'll considerably cut your energy intake and greenhouse gas discharges.

Tunnel pasteurizers are energy-intensive devices, however you can reduce your power consumption by retrofitting them with cutting-edge environmentally friendly technology. This consists of solar-powered heating elements that can operate on renewable energy sources, lowering dependence on nonrenewable fuel sources and your carbon impact.

Another great function of Tunnel pasteurizers is that they work with carbonated beverages, a popular trend among today's health-conscious customers. Unlike flash pasteurizers, which occasionally struggle with high-carbonation levels, Tunnel units can deal with these fizzy mixtures with ease.

zPasteurAIzer can keep track of the performance of your current Tunnel pasteurizer by estimating the collected product quality (PU) value for each and every batch. This allows you to establish if your existing temperature level control system is supplying sufficient warmth therapy in addition to recognizing any type of bent spray heads. read full article can after that readjust the device setups based on your favored PU worths, raising manufacturing efficiency while lowering energy intake. This is a great means to lower your water consumption too, straightening your organization with consumer demand for ecologically liable items.

Tunnel pasteurizers are big industrial-scale makers that warm and great drinks in order to eliminate microorganisms and prolong their life span. Their efficiency relies on precision control.

A number of drink business have retrofitted their existing Tunnel pasteurizers with brand-new eco-friendly technologies to achieve considerable ecological benefits. These include lowered energy consumption, lower water use and reduced greenhouse gas exhausts.

1. Increased Productivity

When you run a brewery, your objective isn't just to eliminate dangerous virus, but also to provide consistency in your products. A well-executed pasteurization procedure not only extends beer's shelf life, but it makes certain that every bottle of your beer will certainly taste the exact same, from your initial set to your last. This is specifically important for craft breweries seeking to bring in health-conscious customers who want the fizzy benefits of soft drinks.

Tunnel pasteurizers work by bringing bottles and containers up to their wanted temperature level in stages, holding them there for long enough to kill off the microorganisms that create putridity. They after that bring them down once more in step-by-step actions until they reach space temperature level, protecting taste accounts. By doing this, they not just prevent microorganisms from increasing in the item, yet they likewise reduce energy consumption by eliminating warmth loss. These are the sort of performance gains that can add up quickly.

2. Decreased Waste

As more emphasis is placed on eco-friendly manufacturing techniques, beverage manufacturers are trying to find ways to reduce their waste manufacturing. Tunnel pasteurizers do a terrific job of this, specifically when they are created and developed by seasoned experts.

Tunnel pasteurizers utilize a series of sprays to heat up the bottles or cans as they move with the device. This removes the need for a big vapor container that eats energy and wastes water. Furthermore, Tunnel pasteurizers make use of a water cost savings system to reuse the warm water utilized in the home heating process, which lowers water and drain usage.

Another advantage of Tunnel pasteurization is its compatibility with soft drinks, which is a big marketing point for craft makers that intend to prolong their items' service life and guarantee consistency between sets. Unlike flash pasteurizers, which in some cases deal with high degrees of carbonation, Tunnel devices can handle these effervescent mixtures without breaking a sweat (or a bottle).

3. Better Item Top Quality

When your drinks are properly treated in Tunnel pasteurizers, they're shielded from dangerous germs while preserving their taste accounts. This indicates your mixtures, sodas, acid maintains (like fruits or acids), and wellness shots can prolong their service life without losing their trademark taste.

In order to accomplish this, passages include specific temperature level control and even circulation throughout their several phases. In addition, conveyor belt speeds help guarantee equal treatment times for each container going into the equipment. All this assists you ensure top quality results every time.

Lastly, tunnels are compatible with carbonated beverages, an expanding fad among health-conscious consumers searching for fizzy choices to sugary soft drinks. Unlike flash pasteurizers, which can struggle with high-carbonation levels, Tunnel machines are created to manage them.

Moreover, visit this hyperlink with power recovery systems decreases water usage too. By utilizing the recovered water for air conditioning, you'll considerably cut your energy intake and greenhouse gas discharges.

4. Reduced Power Intake

Tunnel pasteurizers are energy-intensive devices, however you can reduce your power consumption by retrofitting them with cutting-edge environmentally friendly technology. This consists of solar-powered heating elements that can operate on renewable energy sources, lowering dependence on nonrenewable fuel sources and your carbon impact.

Another great function of Tunnel pasteurizers is that they work with carbonated beverages, a popular trend among today's health-conscious customers. Unlike flash pasteurizers, which occasionally struggle with high-carbonation levels, Tunnel units can deal with these fizzy mixtures with ease.

zPasteurAIzer can keep track of the performance of your current Tunnel pasteurizer by estimating the collected product quality (PU) value for each and every batch. This allows you to establish if your existing temperature level control system is supplying sufficient warmth therapy in addition to recognizing any type of bent spray heads. read full article can after that readjust the device setups based on your favored PU worths, raising manufacturing efficiency while lowering energy intake. This is a great means to lower your water consumption too, straightening your organization with consumer demand for ecologically liable items.

SPOILER ALERT!

Enhancing Performance: Simplifying Your Production Processes With Tunnel Pasteurization Equipment

Short Article Writer-Didriksen Kent

Tunnel pasteurizers are big industrial-scale equipments that warmth and great drinks in order to eliminate microorganisms and prolong their service life. Their efficiency depends on accuracy control.

Numerous drink business have actually retrofitted their existing Tunnel pasteurizers with brand-new environment-friendly innovations to accomplish significant environmental benefits. These include decreased energy intake, reduced water use and reduced greenhouse gas exhausts.

When you run a brewery, your goal isn't just to remove hazardous microorganisms, however also to supply consistency in your products. A well-executed pasteurization procedure not only extends beer's life span, but it makes sure that every container of your beer will taste the exact same, from your very first set to your last. This is specifically essential for craft breweries looking to draw in health-conscious clients who want the carbonated goodness of carbonated drinks.

Tunnel pasteurizers function by bringing bottles and containers approximately their preferred temperature in stages, holding them there for enough time to kill off the microbes that create perishing. They after that bring them down once again in step-by-step steps up until they reach area temperature level, maintaining preference accounts. By doing this, they not just prevent germs from multiplying in the item, but they additionally reduce energy usage by eliminating warmth loss. just click the up coming site are the kinds of effectiveness gains that can add up swiftly.

As more focus is positioned on eco-friendly manufacturing practices, beverage producers are looking for methods to decrease their waste manufacturing. Tunnel pasteurizers do a great job of this, specifically when they are designed and built by seasoned professionals.

Tunnel pasteurizers use a collection of sprays to heat the bottles or cans as they relocate via the equipment. Suggested Browsing eliminates the demand for a huge heavy steam container that consumes energy and drainages. Additionally, Tunnel pasteurizers utilize a water financial savings system to reuse the hot water used in the home heating procedure, which reduces water and sewage system use.

An additional advantage of Tunnel pasteurization is its compatibility with soft drinks, which is a big marketing factor for craft makers who wish to prolong their products' service life and ensure uniformity in between batches. Unlike flash pasteurizers, which sometimes deal with high levels of carbonation, Tunnel systems can deal with these bubbly concoctions without breaking a sweat (or a bottle).

When your drinks are correctly treated in Tunnel pasteurizers, they're secured from damaging bacteria while maintaining their taste profiles. This suggests your brews, sodas, acid maintains (like fruits or acids), and health and wellness shots can prolong their shelf life without shedding their trademark preference.

In order to achieve this, tunnels feature accurate temperature control and also circulation throughout their several phases. In addition, conveyor belt speeds aid ensure equivalent therapy times for every bottle entering the maker. All this helps you assure top quality outcomes whenever.

Lastly, passages are compatible with carbonated beverages, an expanding trend among health-conscious customers looking for carbonated options to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation levels, Tunnel equipments are created to handle them.

Moreover, retrofitting passages with energy recovery systems lowers water use as well. By using the retrieved water for cooling, you'll considerably reduce your power usage and greenhouse gas exhausts.

Tunnel pasteurizers are energy-intensive machines, but you can decrease your energy consumption by retrofitting them with cutting-edge environmentally friendly modern technology. This consists of solar-powered burner that can work on renewable energy sources, decreasing dependence on nonrenewable fuel sources and your carbon footprint.

An additional excellent attribute of Tunnel pasteurizers is that they work with carbonated beverages, a popular fad amongst today's health-conscious customers. Unlike flash pasteurizers, which sometimes struggle with high-carbonation levels, Tunnel units can take care of these fizzy mixtures with ease.

zPasteurAIzer can keep track of the effectiveness of your present Tunnel pasteurizer by estimating the collected product quality (PU) value for every set. This enables you to determine if your current temperature level control system is delivering sufficient warmth therapy as well as determining any type of bent spray heads. You can after that readjust the maker settings based upon your preferred PU worths, boosting manufacturing effectiveness while decreasing power consumption. This is a great way to cut down your water intake also, aligning your business with consumer demand for ecologically liable items.

Tunnel pasteurizers are big industrial-scale equipments that warmth and great drinks in order to eliminate microorganisms and prolong their service life. Their efficiency depends on accuracy control.

Numerous drink business have actually retrofitted their existing Tunnel pasteurizers with brand-new environment-friendly innovations to accomplish significant environmental benefits. These include decreased energy intake, reduced water use and reduced greenhouse gas exhausts.

1. Increased Productivity

When you run a brewery, your goal isn't just to remove hazardous microorganisms, however also to supply consistency in your products. A well-executed pasteurization procedure not only extends beer's life span, but it makes sure that every container of your beer will taste the exact same, from your very first set to your last. This is specifically essential for craft breweries looking to draw in health-conscious clients who want the carbonated goodness of carbonated drinks.

Tunnel pasteurizers function by bringing bottles and containers approximately their preferred temperature in stages, holding them there for enough time to kill off the microbes that create perishing. They after that bring them down once again in step-by-step steps up until they reach area temperature level, maintaining preference accounts. By doing this, they not just prevent germs from multiplying in the item, but they additionally reduce energy usage by eliminating warmth loss. just click the up coming site are the kinds of effectiveness gains that can add up swiftly.

2. Minimized Waste

As more focus is positioned on eco-friendly manufacturing practices, beverage producers are looking for methods to decrease their waste manufacturing. Tunnel pasteurizers do a great job of this, specifically when they are designed and built by seasoned professionals.

Tunnel pasteurizers use a collection of sprays to heat the bottles or cans as they relocate via the equipment. Suggested Browsing eliminates the demand for a huge heavy steam container that consumes energy and drainages. Additionally, Tunnel pasteurizers utilize a water financial savings system to reuse the hot water used in the home heating procedure, which reduces water and sewage system use.

An additional advantage of Tunnel pasteurization is its compatibility with soft drinks, which is a big marketing factor for craft makers who wish to prolong their products' service life and ensure uniformity in between batches. Unlike flash pasteurizers, which sometimes deal with high levels of carbonation, Tunnel systems can deal with these bubbly concoctions without breaking a sweat (or a bottle).

3. Better Product Quality

When your drinks are correctly treated in Tunnel pasteurizers, they're secured from damaging bacteria while maintaining their taste profiles. This suggests your brews, sodas, acid maintains (like fruits or acids), and health and wellness shots can prolong their shelf life without shedding their trademark preference.

In order to achieve this, tunnels feature accurate temperature control and also circulation throughout their several phases. In addition, conveyor belt speeds aid ensure equivalent therapy times for every bottle entering the maker. All this helps you assure top quality outcomes whenever.

Lastly, passages are compatible with carbonated beverages, an expanding trend among health-conscious customers looking for carbonated options to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation levels, Tunnel equipments are created to handle them.

Moreover, retrofitting passages with energy recovery systems lowers water use as well. By using the retrieved water for cooling, you'll considerably reduce your power usage and greenhouse gas exhausts.

4. Lowered Energy Intake

Tunnel pasteurizers are energy-intensive machines, but you can decrease your energy consumption by retrofitting them with cutting-edge environmentally friendly modern technology. This consists of solar-powered burner that can work on renewable energy sources, decreasing dependence on nonrenewable fuel sources and your carbon footprint.

An additional excellent attribute of Tunnel pasteurizers is that they work with carbonated beverages, a popular fad amongst today's health-conscious customers. Unlike flash pasteurizers, which sometimes struggle with high-carbonation levels, Tunnel units can take care of these fizzy mixtures with ease.

zPasteurAIzer can keep track of the effectiveness of your present Tunnel pasteurizer by estimating the collected product quality (PU) value for every set. This enables you to determine if your current temperature level control system is delivering sufficient warmth therapy as well as determining any type of bent spray heads. You can after that readjust the maker settings based upon your preferred PU worths, boosting manufacturing effectiveness while decreasing power consumption. This is a great way to cut down your water intake also, aligning your business with consumer demand for ecologically liable items.

SPOILER ALERT!

Boosting Productivity: Enhancing Your Production Refine Utilizing Tunnel Pasteurization Equipment

Authored By-Didriksen Santana

Tunnel pasteurizers are big industrial-scale makers that heat and amazing beverages in order to eliminate microorganisms and extend their service life. relevant internet page depends upon precision control.

Numerous drink business have retrofitted their existing Tunnel pasteurizers with brand-new environment-friendly technologies to attain substantial ecological advantages. These consist of lowered energy usage, reduced water use and reduced greenhouse gas emissions.

When you run a brewery, your objective isn't simply to eliminate damaging microorganisms, but likewise to supply consistency in your products. A well-executed pasteurization process not just prolongs beer's service life, however it ensures that every bottle of your beer will certainly taste the very same, from your first batch to your last. This is specifically essential for craft breweries looking to bring in health-conscious customers that desire the carbonated goodness of carbonated drinks.

Tunnel pasteurizers function by bringing containers and cans up to their preferred temperature in phases, holding them there for long enough to exterminate the bacteria that trigger spoilage. They then bring them down once again in incremental steps until they reach space temperature, maintaining preference accounts. By doing this, they not just stop germs from multiplying in the product, yet they additionally decrease energy intake by eliminating heat loss. These are the sort of effectiveness gains that can add up swiftly.

As more focus is put on green manufacturing methods, drink manufacturers are trying to find methods to decrease their waste production. Tunnel pasteurizers do a fantastic job of this, especially when they are made and built by seasoned experts.

Tunnel pasteurizers utilize a series of sprays to heat up the bottles or cans as they move through the machine. This gets rid of the need for a huge heavy steam storage tank that eats energy and wastes water. In addition, Tunnel pasteurizers use a water cost savings system to recycle the hot water utilized in the home heating procedure, which reduces water and drain use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a large marketing factor for craft makers that wish to extend their products' shelf life and make sure uniformity between batches. Unlike flash pasteurizers, which occasionally deal with high levels of carbonation, Tunnel devices can deal with these bubbly concoctions without breaking a sweat (or a container).

When your beverages are correctly dealt with in Tunnel pasteurizers, they're secured from harmful bacteria while preserving their taste accounts. This implies your brews, soft drinks, acid preserves (like fruits or acids), and wellness shots can expand their service life without losing their signature preference.

In order to accomplish this, passages feature specific temperature level control and even circulation throughout their several stages. In addition, conveyor belt speeds aid make sure equal treatment times for every bottle going into the equipment. All this assists you assure quality results each time.

Finally, passages are compatible with carbonated beverages, a growing trend amongst health-conscious customers looking for carbonated alternatives to sweet sodas. Unlike flash pasteurizers, which can battle with high-carbonation degrees, Tunnel equipments are created to handle them.

Moreover, retrofitting passages with energy recovery systems minimizes water usage as well. By using the retrieved water for air conditioning, you'll substantially reduce your power usage and greenhouse gas emissions.

Tunnel pasteurizers are energy-intensive equipments, yet you can decrease your energy consumption by retrofitting them with advanced environment-friendly modern technology. This includes solar-powered heating elements that can operate on renewable resource sources, lowering reliance on nonrenewable fuel sources and your carbon footprint.

Another fantastic attribute of Tunnel pasteurizers is that they are compatible with carbonated beverages, a preferred pattern amongst today's health-conscious consumers. Unlike flash pasteurizers, which occasionally deal with high-carbonation degrees, Tunnel systems can handle these fizzy mixtures effortlessly.

zPasteurAIzer can check the efficiency of your existing Tunnel pasteurizer by estimating the accumulated product quality (PU) value for each and every set. This enables you to figure out if your existing temperature control system is delivering enough warm therapy along with recognizing any type of curved spray heads. You can then readjust the maker settings based upon your recommended PU values, enhancing manufacturing effectiveness while decreasing energy consumption. This is a great means to cut down your water consumption also, straightening your business with consumer demand for environmentally accountable products.

Tunnel pasteurizers are big industrial-scale makers that heat and amazing beverages in order to eliminate microorganisms and extend their service life. relevant internet page depends upon precision control.

Numerous drink business have retrofitted their existing Tunnel pasteurizers with brand-new environment-friendly technologies to attain substantial ecological advantages. These consist of lowered energy usage, reduced water use and reduced greenhouse gas emissions.

1. Enhanced Productivity

When you run a brewery, your objective isn't simply to eliminate damaging microorganisms, but likewise to supply consistency in your products. A well-executed pasteurization process not just prolongs beer's service life, however it ensures that every bottle of your beer will certainly taste the very same, from your first batch to your last. This is specifically essential for craft breweries looking to bring in health-conscious customers that desire the carbonated goodness of carbonated drinks.

Tunnel pasteurizers function by bringing containers and cans up to their preferred temperature in phases, holding them there for long enough to exterminate the bacteria that trigger spoilage. They then bring them down once again in incremental steps until they reach space temperature, maintaining preference accounts. By doing this, they not just stop germs from multiplying in the product, yet they additionally decrease energy intake by eliminating heat loss. These are the sort of effectiveness gains that can add up swiftly.

2. Decreased Waste

As more focus is put on green manufacturing methods, drink manufacturers are trying to find methods to decrease their waste production. Tunnel pasteurizers do a fantastic job of this, especially when they are made and built by seasoned experts.

Tunnel pasteurizers utilize a series of sprays to heat up the bottles or cans as they move through the machine. This gets rid of the need for a huge heavy steam storage tank that eats energy and wastes water. In addition, Tunnel pasteurizers use a water cost savings system to recycle the hot water utilized in the home heating procedure, which reduces water and drain use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a large marketing factor for craft makers that wish to extend their products' shelf life and make sure uniformity between batches. Unlike flash pasteurizers, which occasionally deal with high levels of carbonation, Tunnel devices can deal with these bubbly concoctions without breaking a sweat (or a container).

3. Much Better Product Quality

When your beverages are correctly dealt with in Tunnel pasteurizers, they're secured from harmful bacteria while preserving their taste accounts. This implies your brews, soft drinks, acid preserves (like fruits or acids), and wellness shots can expand their service life without losing their signature preference.

In order to accomplish this, passages feature specific temperature level control and even circulation throughout their several stages. In addition, conveyor belt speeds aid make sure equal treatment times for every bottle going into the equipment. All this assists you assure quality results each time.

Finally, passages are compatible with carbonated beverages, a growing trend amongst health-conscious customers looking for carbonated alternatives to sweet sodas. Unlike flash pasteurizers, which can battle with high-carbonation degrees, Tunnel equipments are created to handle them.

Moreover, retrofitting passages with energy recovery systems minimizes water usage as well. By using the retrieved water for air conditioning, you'll substantially reduce your power usage and greenhouse gas emissions.

4. Lowered Energy Usage

Tunnel pasteurizers are energy-intensive equipments, yet you can decrease your energy consumption by retrofitting them with advanced environment-friendly modern technology. This includes solar-powered heating elements that can operate on renewable resource sources, lowering reliance on nonrenewable fuel sources and your carbon footprint.

Another fantastic attribute of Tunnel pasteurizers is that they are compatible with carbonated beverages, a preferred pattern amongst today's health-conscious consumers. Unlike flash pasteurizers, which occasionally deal with high-carbonation degrees, Tunnel systems can handle these fizzy mixtures effortlessly.

zPasteurAIzer can check the efficiency of your existing Tunnel pasteurizer by estimating the accumulated product quality (PU) value for each and every set. This enables you to figure out if your existing temperature control system is delivering enough warm therapy along with recognizing any type of curved spray heads. You can then readjust the maker settings based upon your recommended PU values, enhancing manufacturing effectiveness while decreasing energy consumption. This is a great means to cut down your water consumption also, straightening your business with consumer demand for environmentally accountable products.

SPOILER ALERT!

Enhancing Performance: Improving Your Production Processes With Tunnel Pasteurization Innovation

Short Article By-McNulty Harboe

Tunnel pasteurizers are huge industrial-scale makers that warmth and trendy drinks in order to kill microorganisms and prolong their life span. Their performance depends on accuracy control.

https://www.science20.com/news_articles/micromilk_pasteurizing_milk_microwaves-128001 have retrofitted their existing Tunnel pasteurizers with brand-new eco-friendly technologies to attain substantial ecological benefits. These include decreased power usage, reduced water usage and decreased greenhouse gas exhausts.

When you run a brewery, your goal isn't just to eliminate hazardous microorganisms, yet also to use consistency in your products. A well-executed pasteurization process not just extends beer's service life, yet it guarantees that every bottle of your beer will taste the same, from your very first batch to your last. This is particularly important for craft breweries aiming to attract health-conscious clients that desire the carbonated benefits of carbonated drinks.

Tunnel pasteurizers function by bringing bottles and cans approximately their preferred temperature level in stages, holding them there for long enough to exterminate the bacteria that trigger perishing. They then bring them down once again in step-by-step steps up until they get to space temperature level, preserving preference accounts. By doing this, they not only protect against germs from increasing in the product, but they likewise decrease power consumption by eliminating warm loss. These are the kinds of performance gains that can build up swiftly.

As even more emphasis is put on environment-friendly manufacturing methods, drink suppliers are seeking methods to reduce their waste manufacturing. Tunnel pasteurizers do a wonderful job of this, specifically when they are created and built by skilled professionals.

Tunnel pasteurizers make use of a collection of sprays to warm the bottles or canisters as they move via the equipment. This eliminates the demand for a big heavy steam storage tank that consumes power and drainages. Furthermore, Tunnel pasteurizers utilize a water savings system to reuse the hot water used in the heating procedure, which decreases water and drain usage.

One more benefit of Tunnel pasteurization is its compatibility with carbonated drinks, which is a large marketing point for craft makers who want to prolong their items' service life and ensure consistency in between batches. Unlike flash pasteurizers, which occasionally deal with high degrees of carbonation, Tunnel systems can take care of these effervescent concoctions without breaking a sweat (or a container).

When your drinks are effectively dealt with in Tunnel pasteurizers, they're secured from damaging germs while maintaining their taste profiles. This implies your brews, sodas, acid preserves (like fruits or acids), and health shots can expand their life span without shedding their trademark taste.

In order to achieve this, tunnels include accurate temperature level control and even circulation throughout their multiple stages. Additionally, conveyor belt rates help ensure equivalent treatment times for each and every bottle getting in the device. All this assists you ensure high quality results every single time.

Finally, passages work with carbonated beverages, an expanding pattern amongst health-conscious consumers looking for fizzy options to sugary sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel makers are made to manage them.

In addition, retrofitting tunnels with energy healing systems reduces water use too. By using the retrieved water for cooling, you'll dramatically reduce your power usage and greenhouse gas emissions.

Tunnel pasteurizers are energy-intensive makers, however you can minimize your energy intake by retrofitting them with cutting-edge environment-friendly modern technology. This includes solar-powered heating elements that can work on renewable resource resources, lowering dependence on fossil fuels and your carbon impact.

An additional terrific feature of Tunnel pasteurizers is that they are compatible with carbonated beverages, a preferred pattern among today's health-conscious customers. Unlike flash pasteurizers, which in some cases deal with high-carbonation levels, Tunnel devices can manage these carbonated mixtures easily.

zPasteurAIzer can check the efficiency of your present Tunnel pasteurizer by estimating the collected product quality (PU) worth for each set. This allows you to determine if your current temperature level control system is delivering sufficient heat therapy as well as determining any curved spray heads. You can after that adjust the equipment setups based on your preferred PU values, raising manufacturing efficiency while decreasing power usage. mouse click the following web page is a great method to cut down your water intake as well, straightening your service with consumer demand for eco liable products.

Tunnel pasteurizers are huge industrial-scale makers that warmth and trendy drinks in order to kill microorganisms and prolong their life span. Their performance depends on accuracy control.

https://www.science20.com/news_articles/micromilk_pasteurizing_milk_microwaves-128001 have retrofitted their existing Tunnel pasteurizers with brand-new eco-friendly technologies to attain substantial ecological benefits. These include decreased power usage, reduced water usage and decreased greenhouse gas exhausts.

1. Boosted Efficiency

When you run a brewery, your goal isn't just to eliminate hazardous microorganisms, yet also to use consistency in your products. A well-executed pasteurization process not just extends beer's service life, yet it guarantees that every bottle of your beer will taste the same, from your very first batch to your last. This is particularly important for craft breweries aiming to attract health-conscious clients that desire the carbonated benefits of carbonated drinks.

Tunnel pasteurizers function by bringing bottles and cans approximately their preferred temperature level in stages, holding them there for long enough to exterminate the bacteria that trigger perishing. They then bring them down once again in step-by-step steps up until they get to space temperature level, preserving preference accounts. By doing this, they not only protect against germs from increasing in the product, but they likewise decrease power consumption by eliminating warm loss. These are the kinds of performance gains that can build up swiftly.

2. Decreased Waste

As even more emphasis is put on environment-friendly manufacturing methods, drink suppliers are seeking methods to reduce their waste manufacturing. Tunnel pasteurizers do a wonderful job of this, specifically when they are created and built by skilled professionals.

Tunnel pasteurizers make use of a collection of sprays to warm the bottles or canisters as they move via the equipment. This eliminates the demand for a big heavy steam storage tank that consumes power and drainages. Furthermore, Tunnel pasteurizers utilize a water savings system to reuse the hot water used in the heating procedure, which decreases water and drain usage.

One more benefit of Tunnel pasteurization is its compatibility with carbonated drinks, which is a large marketing point for craft makers who want to prolong their items' service life and ensure consistency in between batches. Unlike flash pasteurizers, which occasionally deal with high degrees of carbonation, Tunnel systems can take care of these effervescent concoctions without breaking a sweat (or a container).

3. Better Product High Quality

When your drinks are effectively dealt with in Tunnel pasteurizers, they're secured from damaging germs while maintaining their taste profiles. This implies your brews, sodas, acid preserves (like fruits or acids), and health shots can expand their life span without shedding their trademark taste.

In order to achieve this, tunnels include accurate temperature level control and even circulation throughout their multiple stages. Additionally, conveyor belt rates help ensure equivalent treatment times for each and every bottle getting in the device. All this assists you ensure high quality results every single time.

Finally, passages work with carbonated beverages, an expanding pattern amongst health-conscious consumers looking for fizzy options to sugary sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel makers are made to manage them.

In addition, retrofitting tunnels with energy healing systems reduces water use too. By using the retrieved water for cooling, you'll dramatically reduce your power usage and greenhouse gas emissions.

4. Decreased Energy Intake

Tunnel pasteurizers are energy-intensive makers, however you can minimize your energy intake by retrofitting them with cutting-edge environment-friendly modern technology. This includes solar-powered heating elements that can work on renewable resource resources, lowering dependence on fossil fuels and your carbon impact.

An additional terrific feature of Tunnel pasteurizers is that they are compatible with carbonated beverages, a preferred pattern among today's health-conscious customers. Unlike flash pasteurizers, which in some cases deal with high-carbonation levels, Tunnel devices can manage these carbonated mixtures easily.

zPasteurAIzer can check the efficiency of your present Tunnel pasteurizer by estimating the collected product quality (PU) worth for each set. This allows you to determine if your current temperature level control system is delivering sufficient heat therapy as well as determining any curved spray heads. You can after that adjust the equipment setups based on your preferred PU values, raising manufacturing efficiency while decreasing power usage. mouse click the following web page is a great method to cut down your water intake as well, straightening your service with consumer demand for eco liable products.

SPOILER ALERT!

Enhancing Performance: Simplifying Your Production Procedures With Tunnel Pasteurization Technology

Web Content By-Moran Childers

Tunnel pasteurizers are huge industrial-scale equipments that warmth and cool drinks in order to eliminate microorganisms and extend their shelf life. Their efficiency depends on precision control.

Numerous drink business have retrofitted their existing Tunnel pasteurizers with brand-new environmentally friendly modern technologies to accomplish substantial environmental benefits. These consist of lowered power consumption, reduced water use and decreased greenhouse gas exhausts.

When you run a brewery, your objective isn't simply to remove dangerous microorganisms, but additionally to offer uniformity in your products. A well-executed pasteurization procedure not just lengthens beer's shelf life, however it guarantees that every bottle of your beer will taste the same, from your very first set to your last. This is particularly vital for craft breweries seeking to draw in health-conscious clients that want the fizzy goodness of carbonated drinks.

Tunnel pasteurizers work by bringing bottles and containers as much as their preferred temperature level in phases, holding them there for enough time to exterminate the microbes that cause putridity. They then bring them down once more in step-by-step steps till they get to space temperature, maintaining taste profiles. By doing this, they not only avoid bacteria from increasing in the item, but they additionally lower energy intake by removing heat loss. These are the kinds of effectiveness gains that can build up swiftly.

As more focus is positioned on environment-friendly manufacturing methods, drink manufacturers are seeking means to lower their waste manufacturing. Tunnel pasteurizers do a great job of this, particularly when they are created and constructed by skilled experts.

Tunnel pasteurizers make use of a collection of sprays to warm the bottles or cans as they relocate through the equipment. This gets rid of the requirement for a big steam tank that consumes energy and drainages. Additionally, Read More Listed here use a water savings system to reuse the hot water made use of in the home heating process, which minimizes water and sewer usage.

One more benefit of Tunnel pasteurization is its compatibility with soft drinks, which is a big marketing factor for craft brewers who want to expand their products' shelf life and make certain uniformity between batches. Unlike flash pasteurizers, which occasionally fight with high degrees of carbonation, Tunnel units can manage these bubbly concoctions without breaking a sweat (or a container).

When your drinks are effectively treated in Tunnel pasteurizers, they're secured from dangerous germs while maintaining their taste profiles. This suggests your mixtures, sodas, acid preserves (like fruits or acids), and health shots can extend their shelf life without shedding their trademark taste.

In order to accomplish this, tunnels include specific temperature level control and even circulation throughout their numerous phases. Furthermore, conveyor belt rates help make sure equal therapy times for every container getting in the equipment. All this assists you assure quality results every single time.

Lastly, passages are compatible with carbonated beverages, an expanding pattern among health-conscious customers looking for fizzy alternatives to sugary sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel machines are developed to handle them.

Moreover, retrofitting tunnels with power healing systems decreases water use also. By using the recovered water for cooling, you'll dramatically cut your energy usage and greenhouse gas exhausts.

Tunnel pasteurizers are energy-intensive equipments, however you can decrease your power usage by retrofitting them with cutting-edge environmentally friendly technology. This consists of solar-powered burner that can work on renewable resource sources, decreasing reliance on nonrenewable fuel sources and your carbon footprint.

Another terrific feature of Tunnel pasteurizers is that they work with carbonated beverages, a popular pattern amongst today's health-conscious customers. Unlike flash pasteurizers, which occasionally fight with high-carbonation degrees, Tunnel devices can deal with these fizzy mixtures effortlessly.

zPasteurAIzer can monitor the effectiveness of your existing Tunnel pasteurizer by estimating the accumulated product quality (PU) value for each and every batch. This enables you to identify if your existing temperature control system is delivering enough heat therapy along with identifying any kind of bent spray heads. You can then change the device settings based on your favored PU worths, boosting production effectiveness while decreasing power consumption. This is an excellent means to cut down your water usage too, aligning your service with consumer demand for environmentally accountable products.

Tunnel pasteurizers are huge industrial-scale equipments that warmth and cool drinks in order to eliminate microorganisms and extend their shelf life. Their efficiency depends on precision control.

Numerous drink business have retrofitted their existing Tunnel pasteurizers with brand-new environmentally friendly modern technologies to accomplish substantial environmental benefits. These consist of lowered power consumption, reduced water use and decreased greenhouse gas exhausts.

1. Enhanced Productivity

When you run a brewery, your objective isn't simply to remove dangerous microorganisms, but additionally to offer uniformity in your products. A well-executed pasteurization procedure not just lengthens beer's shelf life, however it guarantees that every bottle of your beer will taste the same, from your very first set to your last. This is particularly vital for craft breweries seeking to draw in health-conscious clients that want the fizzy goodness of carbonated drinks.

Tunnel pasteurizers work by bringing bottles and containers as much as their preferred temperature level in phases, holding them there for enough time to exterminate the microbes that cause putridity. They then bring them down once more in step-by-step steps till they get to space temperature, maintaining taste profiles. By doing this, they not only avoid bacteria from increasing in the item, but they additionally lower energy intake by removing heat loss. These are the kinds of effectiveness gains that can build up swiftly.

2. Minimized Waste

As more focus is positioned on environment-friendly manufacturing methods, drink manufacturers are seeking means to lower their waste manufacturing. Tunnel pasteurizers do a great job of this, particularly when they are created and constructed by skilled experts.

Tunnel pasteurizers make use of a collection of sprays to warm the bottles or cans as they relocate through the equipment. This gets rid of the requirement for a big steam tank that consumes energy and drainages. Additionally, Read More Listed here use a water savings system to reuse the hot water made use of in the home heating process, which minimizes water and sewer usage.

One more benefit of Tunnel pasteurization is its compatibility with soft drinks, which is a big marketing factor for craft brewers who want to expand their products' shelf life and make certain uniformity between batches. Unlike flash pasteurizers, which occasionally fight with high degrees of carbonation, Tunnel units can manage these bubbly concoctions without breaking a sweat (or a container).

3. Better Product Quality

When your drinks are effectively treated in Tunnel pasteurizers, they're secured from dangerous germs while maintaining their taste profiles. This suggests your mixtures, sodas, acid preserves (like fruits or acids), and health shots can extend their shelf life without shedding their trademark taste.

In order to accomplish this, tunnels include specific temperature level control and even circulation throughout their numerous phases. Furthermore, conveyor belt rates help make sure equal therapy times for every container getting in the equipment. All this assists you assure quality results every single time.

Lastly, passages are compatible with carbonated beverages, an expanding pattern among health-conscious customers looking for fizzy alternatives to sugary sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel machines are developed to handle them.

Moreover, retrofitting tunnels with power healing systems decreases water use also. By using the recovered water for cooling, you'll dramatically cut your energy usage and greenhouse gas exhausts.

4. Reduced Energy Usage